words

Scraping

There is an excerpt in the movie "Superman" where the leading character pauses to reflect why he couldn't accomplish one specific deed, given that he had tremendous powers at his command. When Andy Rheault called and asked me to write a follow-up article on hand scraping, I felt similarly: Why not an article on line-boring fifty-seven cam boxes, modified pressure angles on thirty-seven oil pump gears, babbitting forty-nine connecting rods, dynamic balancing U-16 rotating members? Why hand scraping? My shuddering at his request is because this particular subject follows the old transcendental theme: knowledge throug suffering. It is the one activity of the hundreds that I do and teach that is the least likely to be learned by being instructed. The only way to learn this particular art form is by choosing to accept a sore back and calloused hands.

Years ago, Bunny Phillips wrote an article on hand scraping that appeared in Pur Sang (12/2) and was later reprinted in Bugantics. What follows are simply comments addressed to those who might find additional instruction helpful.

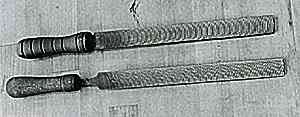

The first and often overlooked step in this process is to insure that the arting lines on the castings mate accurately. Bolt the cam-box lids to the cam boxes, just as they would be as assembled onto the engine, and run your finger across the joint. If where the two castings meet is not continuous, draw file with a curved-tooth, milled vixen file of the type shown in the phot until the parting line is smooth to the touch. Do not be tempted to use any other kind of file.

Bugatti Hand Scraping

text and photos by Chris Leydon

Published in Pur Sang, Spring 1992, Vol. 32, No. 2

The second step is to created a fine and even finish on the rest of the castings. You must remove all traces of the original scrape marks as well as other imperfections before new scraping can begin. It's very much like preparing a fine finish on wood. I start with 180 wet/dry paper and work through a succession of finer grades and finish with 600 grit wet/dry. Staring with a 400 or 600 grit will just waste a lot of time and muscle power. I do not use water as my wet medium. Water has the propensity to imbed impurities into the casting and provide an insufficient boudary layer while sanding. I use parts cleaning solvent although kerosene will do fine. I aslo use a sanding block to insure that flat castings remain flat and do not become dished in the sanding effort.

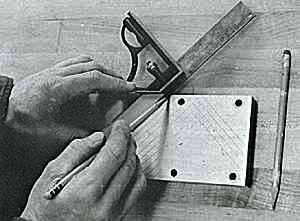

After the parts are cleaned and dried, I lay out the scraping pattern in a grid of intersecting lines placed at 45 degrees to the axis of the casting. Bunny Phillips uses a 3/8" spacing. I find this pattern too tight for the signature of my work; however, when I lay the pattern out for 1/2" spacing, the square formed by the two angled lines is very close to 3/8". From the Types 35, 37, 49, 57, 59 engines I have rebuilt, this pattern follows the original. I use a combination square on which I apply masking tape to top, bottom, and side surface to guard the virgin surface from unwanted distress. Use only wooden pencils. When the tip of the mechanical variety breaks, you will gouge the surface and end up starting all over again. It is important to start your grid at the top of the pieces to be scraped and extend them down to the sides.

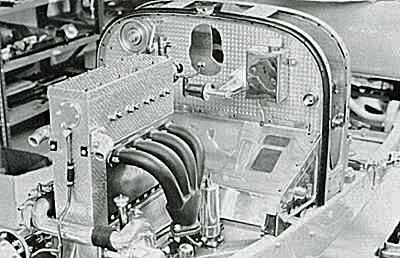

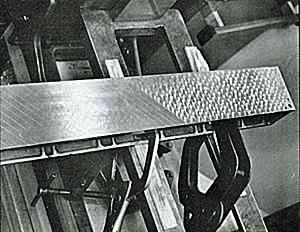

[The above] photo shows the Anderson hand scraper poised at 50 degrees to an original Type 45 cam-box cover. I found through trial and error that the best radius of curvature for scraping a flat surface is 3" which coincidentally appears to be the radius used by at least some apprentices at the factory. Only the rear cam drives on the 57 require a more generous radius for which I keep an additional blade.

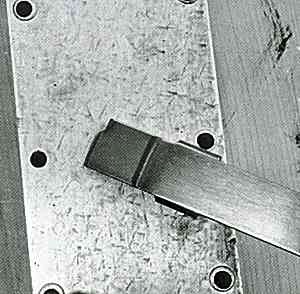

There are three additional considerations in the preparation toward the odyssey of hand scraping (after which you may have your own saga with which to grace Pur Sang). Aluminum comes in a variety of alloys, fully annealed to fully heat-treated. Each responds to hand scraping in a different way just as machining different aluminum alloys requires different tool angles, cutter speeds, feeds, etc. Unless you are working with new castings, you will probably be scraping "dead soft" material. Obtain a sample of aluminum (1100-0 or 3003-0) as a practice piece. Don't even think about working on the original until you have developed a rhythm and acceptable finish on a practice piece. Lay out the identical grid pattern as on the original and wet the entire surface with CRC. This is an important step and will factor into your success. As shown below, figuring out how to secure your work while trying to scrape may require some creativity.

With preparation finished, be forewarned no written article will adequately describe the process. To learn how, you must simply dig in and do it. No pain, no gain. Because I know of no factory photos showing workers applying a scraped finish, I have included photos of how it is done in my shop. Bunny Phillips described his technique from the perspective of a left-handed artisan; my photos are from a right-handed perspective. Notice that the scraping tool is held at about 50 degrees to the work piece and is rotated so that it only makes contact with the work piece on its right front leading edge. I usually make a mark on the tool just inside the edge and align this mark on the right top corner of the square I intend to scrape. As my left hand hits the shank of the tool at about a third the way up from the bottom, it has a tendency to rotate the tool counter clockwise while driving it backwards. This produces a comma-like pattern. The tool rests on the shoulder in anticipation of the "hit." Notice the torn condition of the glove on the left hand. Perhaps "real men" don't use a glove; however, I must use a micrometer for a living.

This article is written to encourage and guide those enthusiasts who want to give hand scraping a try. No other finish is as distinctive and in the Bugatti idiom as the hand-scraped finish. If you master the art, try your Bridgeport bed ways as an encore. Good luck!